This is can be dependent on a number of factors but is largely a function of the preload force the force exerted in compressing the bolt and the tension force the force exerted in pulling the bolt apart.

Air cylinder clamping force calculation.

See table below for how much clamping force is available from manual clamp straps of various sizes with a 2 to 1 clamping force ratio to compare with power clamp forces.

Sometimes an approximate method is good enough.

The diameter of the push rod must.

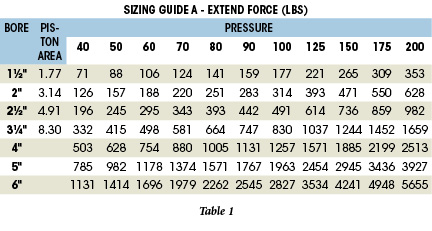

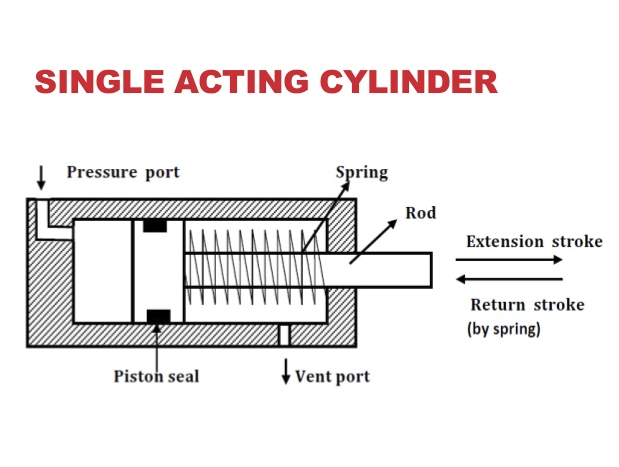

Understand that the 1 256 4 pounds of force would be on the push stroke only and not on the retraction end of the cylinder.

Clamping force calculations can be quite complicated.

All information contained within the pneumatics online web site is the property of pneumatics online.

Reproduction redistribution or modification of the information is prohibited without the express written permission of pneumatics online.

To calculate clamping forces by fea method for hydraulic pressure of 3 5 mpa and force of 5570n using ansys software we consider fixture clamp design model from cad software.

The clamping force on a bolt is defined as the compressive force a fastener exerts on a joint.

Cylinder force calculator imperial units air pressure.

Generated force this is the force generated by a piston cylinder of a specified diameter and applied pressure and can be displayed in a choice of different force measurement units.

The force exerted by a single acting pneumatic cylinder with 1 bar 10 5 n m 2 and full bore diameter of 100 mm 0 1 m can be calculated as.

F p π d 2 4 10 5 n m 2 π 0 1 m 2 4 785 n 0 785 kn air cylinder pressure force diagram.

Therefore for fea import piston clamp lever cad model in ansys static workbench and define contacts between piston small pin and clamp lever respectively.

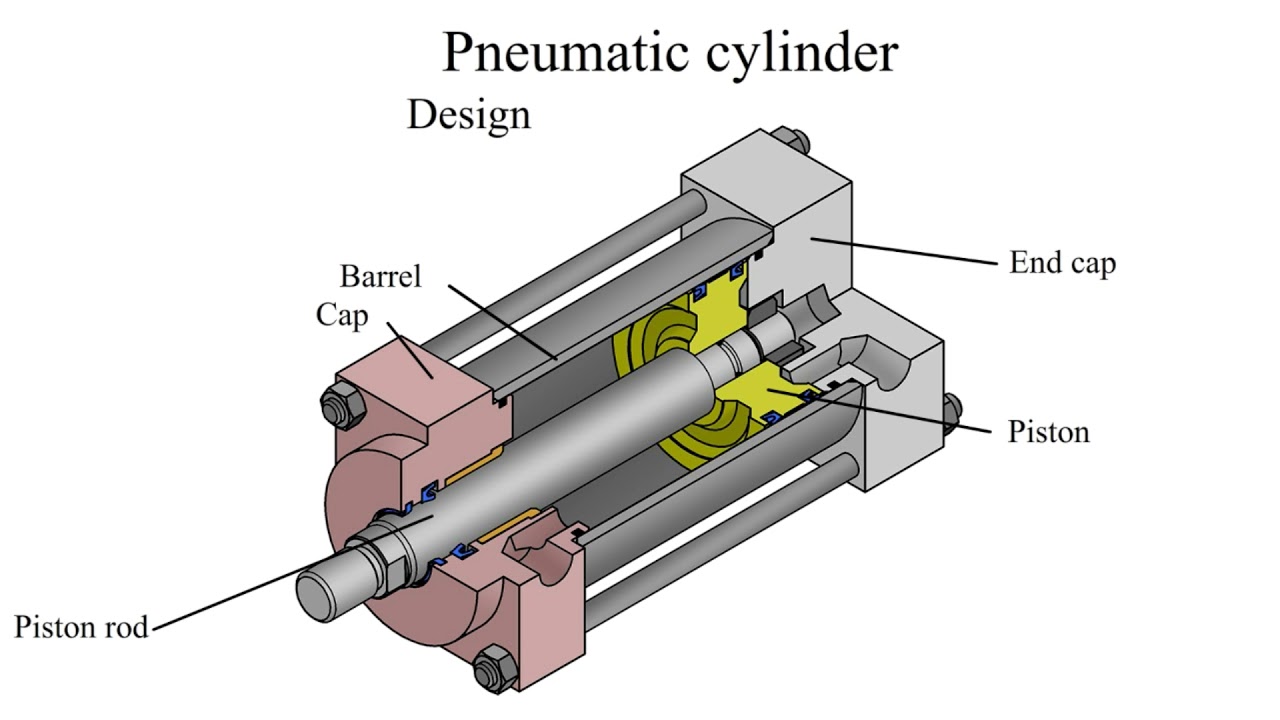

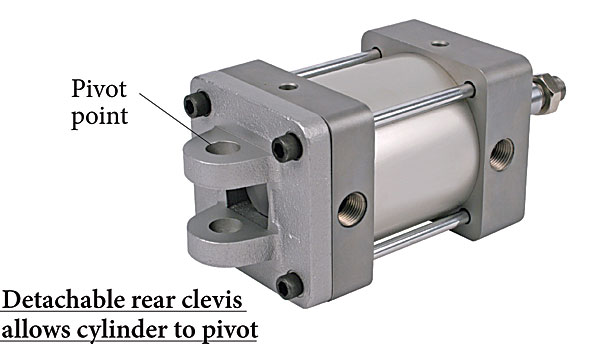

Here s a look at different types how to calculate force speed and air consumptions available options and when to consider special designs.

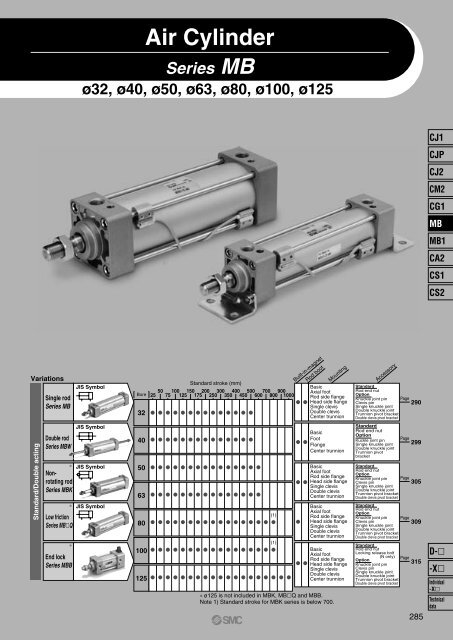

Pneumatic cylinders come in thousands of variations.

Example single acting piston.