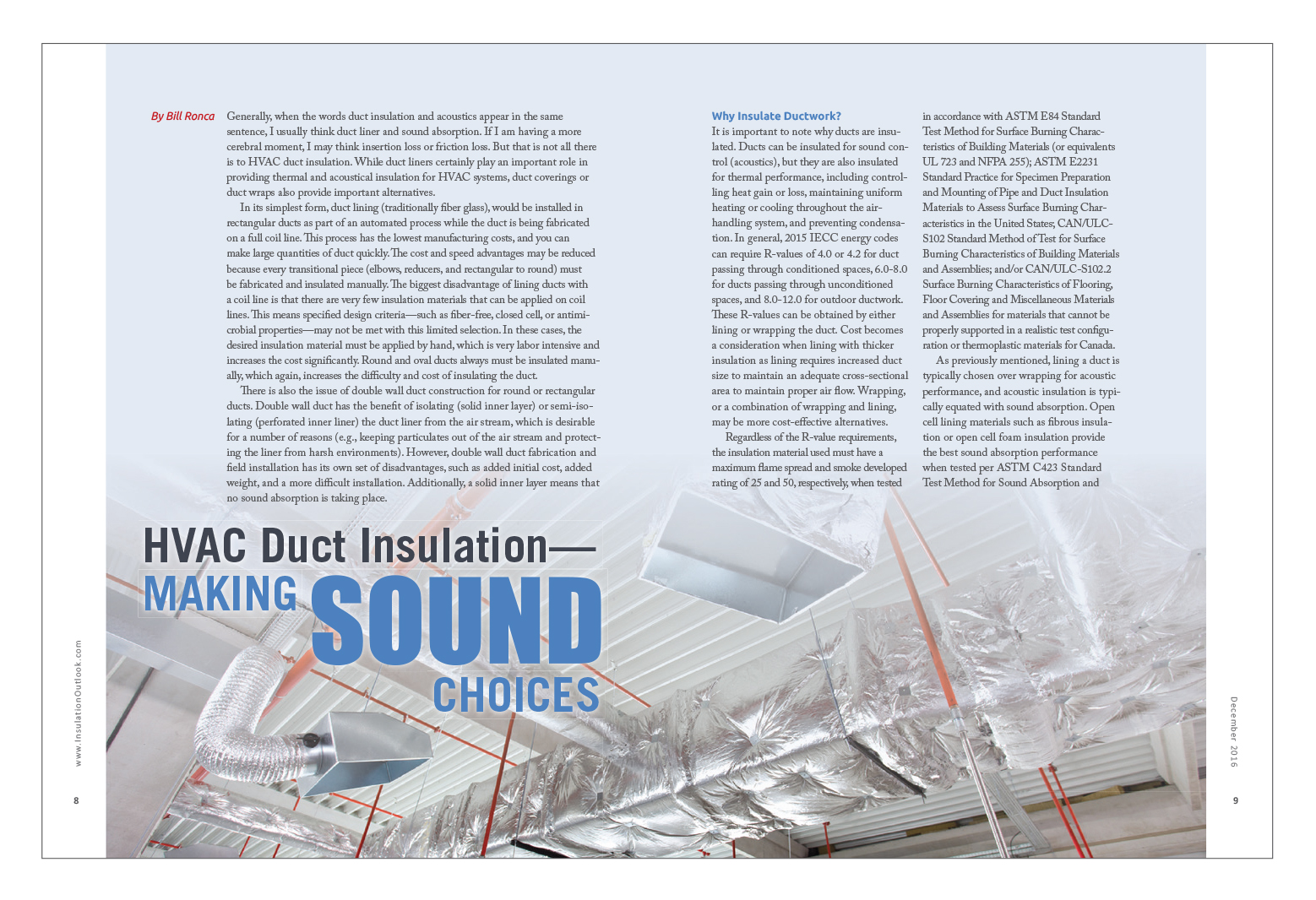

Fibrous glass duct wrap insulation is designed for application to the exteriors of commercial and residential sheet metal heating ventilating and air conditioning ducts and plenums operating at temperatures between 40 f 4 c and 250 f 121 c.

Air duct insulation thickness calculation.

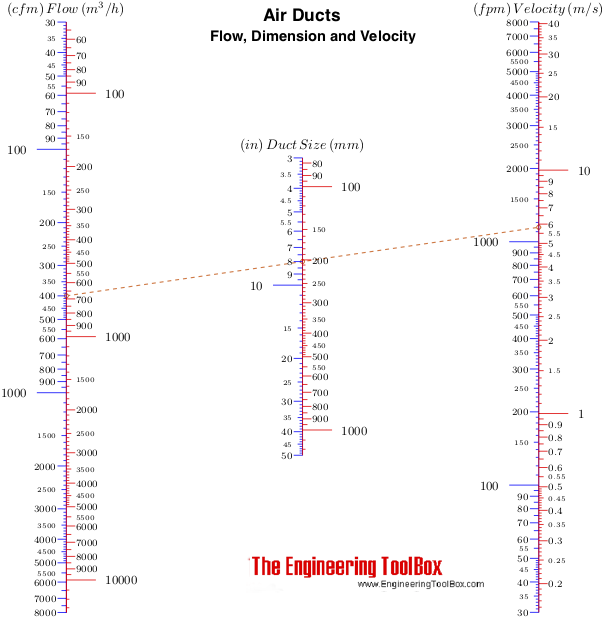

Duct velocity calculate velocities in circular and rectangular ducts imperial and si units online calculator.

3 2sufficient thermal insulation thickness tm 6 c φ 65 td 22 8 c ta 30 c r flex st kalınlık 9 mm ts 23 6 c td 22 8 c thermal insulation material with a high µ value no condensation.

Enter the length of the duct run in feet.

Some other factors to consider.

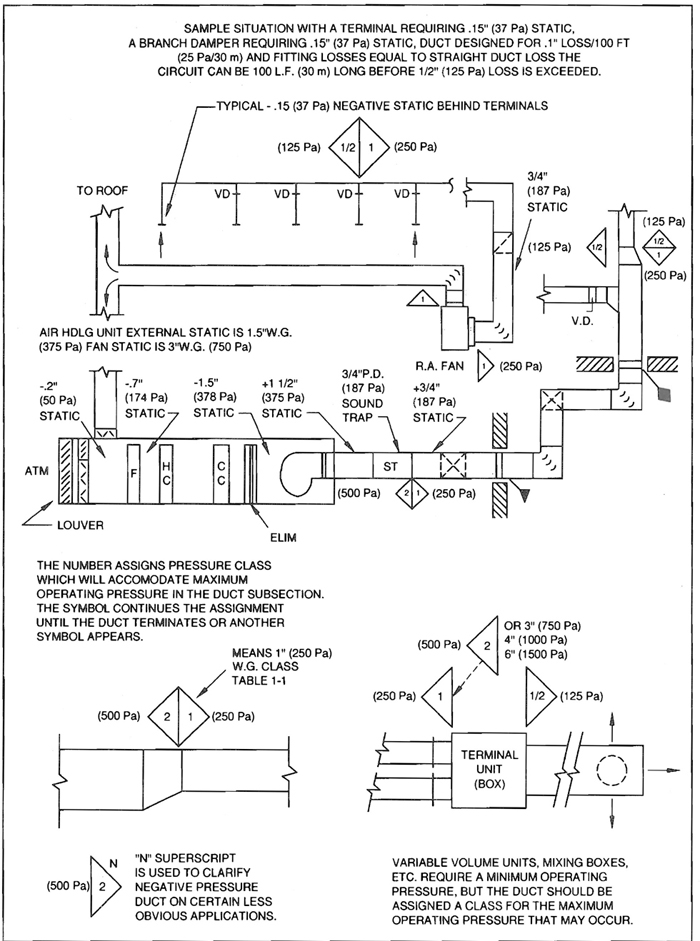

Local resistance pressure loss general calculation.

Air and is a useful tool in air conditioning calculations.

Enter the r value of the selected duct insulation.

Thermal insulation and ductwork heat loss calculation.

Ductwork seal classes ductwork prone to air leakages.

Enter the perimeter of the duct in inches.

Mass air flow rate unit converter.

Enter the ambient temperature the average temperature of the air surrounding the duct line 3.

Heat conduction and thermal resistance.

This chart can be.

There is a high amount of backflow here which again increases the static pressure and reduces the amount of air delivery.

How often do you think you get the full labeled r value.

Air state calculation during heating and heater output.

The tee section at the far end of the main duct causes the air to suddenly divide and change direction.

Hvac calculations and duct sizing gary d.

Duct wrap insulation reduces heat loss or gain through duct walls conserving energy.

Ductwork specific pressure loss calculation.

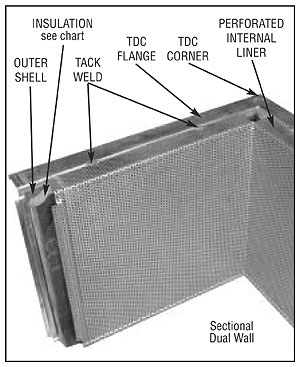

Air handling ductwork cross section design.

R 6 duct insulation 6 305 btu hour 0 53 ton r 4 2 duct insulation 7 948 btu hour 0 66 ton the numbers are even higher for the additional heating load.

Ventilation systems for ventilation and air handling air change rates ducts and pressure drops charts and diagrams and more.

The duct insulation r values i mentioned above are what s on the product label.

A diffusion tight application is a must minimum insulation thickness 7 6 mm tube diameter 25 4 mm.

General formula to calculate minimum insulation thickness required to prevent condensation t k r t1 t2 t3 t1 where t insulation thickness in k thermal conductivity r surface temperature resistance t1 dew point temperature.

Enter the flow rate of the air carried by the duct in cubic feet per minute.