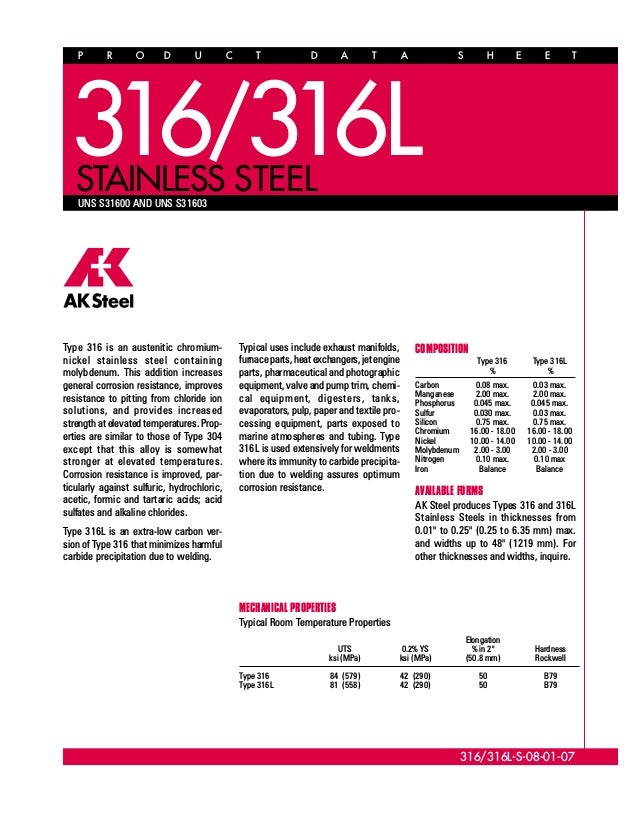

This addition increases general corrosion resistance improves resistance to pitting from chloride ion solutions and provides increased strength at elevated temperatures.

Ak steel product data sheet 316.

Ak steel 316 316l stainless steel data sheet.

Alloy 316 316l is subject to work hardening during deformation and is subject to chip breaking.

Stainless steels for automotive applications like exhaust systems represent a major part of this business segment.

The lower carbon content in 304l minimizes deleterious or harmful carbide precipitation as a result of welding.

The information and data in this product data sheet are accurate to the best of our knowledge and.

316 316l stainless steel product description.

Stainless steel strip.

Types 316 and 316l sheet and strip are covered by the following specifications.

Ak steel produces types 316 and 316l in thicknesses from 0 01 0 25 in.

0 25 6 35 mm and widths up to 48 in.

This page has links to all data sheets in matweb for the manufacturer ak steel.

We have several search tools listed above that give you more efficient methods to reach the information that you need.

Nominal analysis weight percent 800 458 7273 or 814 678 4100 uns s21800.

Ak steel has 211 material s in the matweb database.

304l can therefore be used as welded in severe corrosion environments and it eliminates the need for annealing.

The corrosion resistance of armco nitronic 60 stainless steel falls between that of types 304 and 316.

Type 304 stainless steel is considered to resist pitting and crevice corrosion in waters containing up to about 100 ppm chloride.

Nitronic 60 stainless steel the information and data contained in this product data sheet are intended for general information and do not constitute any warranty expressed or implied of suitability for any applications or design.

Ak steel technical data sheets.

Type 304l stainless steel type 304l stainless steel is an extra low carbon version of the 304 steel alloy.

However experience shows that in a wear system a galling or siezure failure occurs first followed by dimensional loss due to wear and finally corrosion.

Type 316 type 316l ams 5524.

The pre n of type 316 and 316l 24 2 is better than that of type 304 pre n 19 0 reflecting the better pitting resistance which type 316 or 316l offers due to its mo content.

The best machining results are achieved with slower speeds heavier feeds excellent lubrication sharp tooling and powerful rigid equipment.